FRAMING

STD P200

Spine: SkyShark P200, 800mm + FSD split nock + inside brass weigth (diameter 6mm, lenth 70mm)

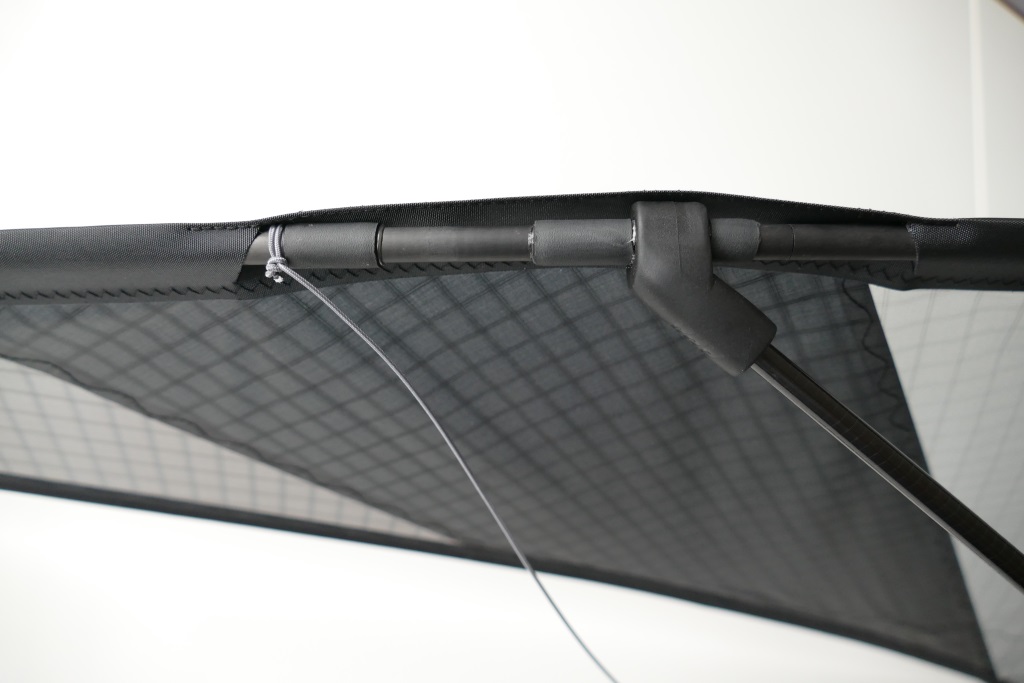

Upper Spreader: 5mm pultruded carbon 495mm

Lower Spreaders: Skyshark 5PT 660mm + Center Cross SkyShark

Leading Edge: SkyShark P200, 1450mm (800-825mm + 625-650mm)

Standoffs: 3mm carbon rod, 270mm distance sail to spreader

Tailweight: ca. 17,5 gr

STD 5PT

Spine: SkyShark P2X, 800mm + FSD split nock + brass weigth inside (diameter 6mm, lenth 70mm)

Upper Spreader: 5mm pultruded carbon 495mm

Lower Spreaders: Skyshark 5PT 660mm + Center Cross SkyShark

Leading Edge: SkyShark 5PT, 1450mm (800-825mm + 625-650mm, cut the thin end of lower part)

Standoffs: 3mm wrapped fiberglass, 270mm distance sail to spreader

Tailweight: ca. 17,5 gr

LW 3PT

Same sail shape as STD. The leading edge tunnels are made of spinnaker nylon instead of dacron.

Spine: SkyShark P1X, 800mm + FSD split nock + brass weigth inside (diameter 6mm, lenth 80mm)

Upper Spreader: 5mm pultruded carbon 495mm

Lower Spreaders: Skyshark 3PT 660mm + Center Cross SkyShark

Leading Edge: SkyShark 3PT, 1450mm (800-825mm + 625-650mm, cut the thin end of lower part)

Standoffs: 3mm carbon, 270mm distance sail to spreader

Tailweight: ca. 20 gr

[Return] @ SPO 📷 by Ulzburger

BRIDLE

Upper: 50 cm

Outer: 47 cm

Inner: 56 cm

DETAILS

DOCUMENTS

- Plan and Overview

- Panels with 6mm extra for the seams

- Output from the kite plan generator

- Shopping lists (in german)

Building notes

- The Leading Edge cutouts are measured from the wingtip, indicated by 0 mm on the plan file

- The center panel is one piece

- Before making the cuts in the leading edge, reinforce the dacron on the inside with a short piece of glass fiber tape. Alternative: Using mylar coated dacron (mylar inside)

- Position of the APA standoff connector on the Lower Spreader: 30 cm from thick end of spar to middle of APA

- For the UL version: The leading edge tunnels are made of spinnaker nylon instead of dacron.

Links

- Click on this link to open the colorizers page by Katzengrafik.

- Some colorizer examples for inspiration by Birger

- Thread on drachenforum.de

- Thread on GWTW-forum

- Thread on Fractured Axel forum

Sugarbaker’s [Return] Building Tutorial vlog

This will be a series of videos showing how I (Stephen Sugarbaker) build kites, and hopefully some good insight for those who want to start making their own.

Video’s

Return Evolved from Dotmatrix on Vimeo.

VF34 from Krijn Hemminga on Vimeo.

![[Return] Plan](https://www.kareloh.com/wordpress/wp-content/uploads/2017/09/Return_LS-389x300.jpg)